Choosing a new supplier is filled with risk. Their website looks professional, but you have no idea what their factory floor really looks like.

An ISO certificate means a factory has official, documented systems for managing quality, safety, or environmental impact. It shows their processes meet a global standard for consistency and reliability, making them a lower-risk partner.

When our boss Mr. Huang, an engineer, started this business from scratch, his focus was purely on building a great alternator. But as we grew, he realized that building a great company was just as important. One of the first major decisions we made was to get ISO 9001 certified. It was a huge amount of work, but it was fundamental. It forced us to create a system for everything we do. For a project manager like you, that certificate on a supplier's wall is more than just a piece of paper. It's the first signal that they take quality seriously. But it's only the first signal, and your job requires you to look deeper.

You see the logo "ISO 9001" on websites and brochures all the time. But what organization is behind it, and what do they actually do?

ISO is the International Organization for Standardization. It is an independent, non-governmental body that develops and publishes international standards. It does not issue certificates itself; third-party auditors do.

Think of ISO as the world's largest publisher of rulebooks for business. These rulebooks are written by global panels of experts from countless industries. They create a blueprint for the best way to do things, whether it's managing a quality system, protecting the environment, or ensuring worker safety. It’s important to understand that ISO creates the standard, but they don't go out and inspect factories. That job is done by independent certification bodies. These auditors visit a factory to check if its processes follow the rules laid out in the ISO standard. If they pass the audit, they get the certificate. So, when you see an ISO certificate, it means an impartial expert has verified that the factory has a working, documented system in place. It's a powerful, third-party endorsement of their operational maturity.

The key takeaway is that ISO provides the framework for excellence. It’s a set of proven best practices that any organization can adopt. The goal is to make industries more efficient and to make trade between countries easier and safer because everyone is following a similar set of rules.

You've probably seen different ISO numbers like 9001 or 14001. Are they all the same? Knowing the difference helps you evaluate a supplier's strengths.

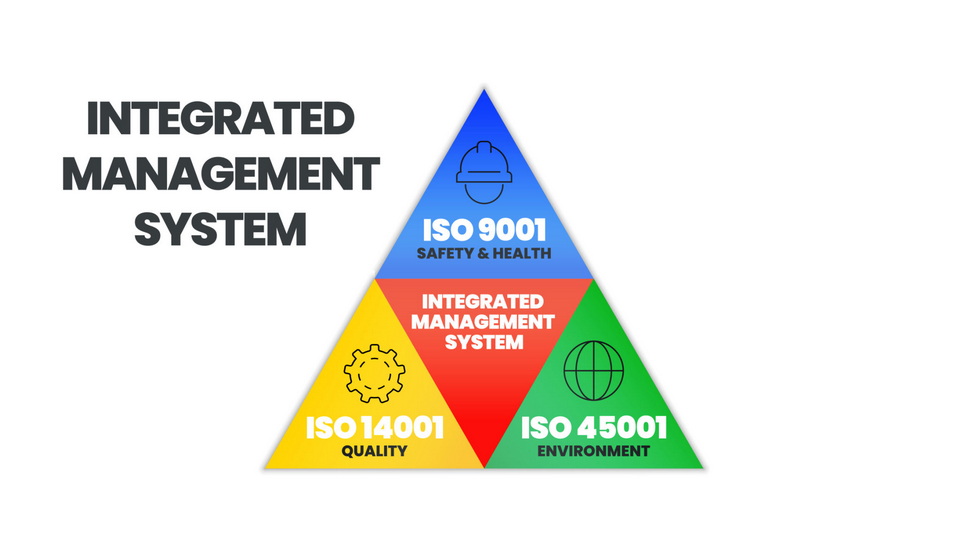

The most common and important ISO standards for factories are ISO 9001 (Quality Management), ISO 14001 (Environmental Management), and ISO 45001 (Occupational Health and Safety). Each addresses a critical area of operations.

When you review a potential supplier, these three certificates tell you a very specific story about their priorities. A factory can have one, two, or all three. As a project manager, you can use these to judge if a supplier's values align with your own company's requirements. At Longkai, we maintain all three of these certifications because we believe they are interconnected. You can't have sustainable quality without also caring for your people and your environmental impact. It's a complete picture of a responsible manufacturing operation. Understanding what each one means allows you to ask smarter questions and better assess the risk of bringing on a new partner.

| Standard | What It Covers | Why It Matters to You, the Buyer |

|---|---|---|

| ISO 9001 | Quality Management System. It covers everything from how raw materials are inspected to final product testing and handling customer feedback. | This is the most important one for product quality. It means the factory has a predictable process, leading to fewer defects and more consistent products. |

| ISO 14001 | Environmental Management System. It provides a framework for measuring and improving environmental impact, like reducing waste and energy use. | This shows the supplier is environmentally responsible and less likely to face shutdowns or fines that could disrupt your supply chain. |

| ISO 45001 | Occupational Health and Safety. This standard focuses on eliminating hazards and creating better, safer working conditions to prevent work-related injuries. | A supplier with this certificate likely has a stable, more motivated workforce. It's a strong indicator of an ethical and well-managed company. |

Some might say a certificate is just a piece of paper. But in manufacturing, where consistency is everything, why is that paper so important?

ISO is important because it forces a manufacturer to move from random actions to structured processes. This creates a culture of consistency, continuous improvement, and accountability, which directly results in a more reliable product.

Getting and keeping an ISO certificate is a major commitment. I remember when we first went through the ISO 9001 process. It was a huge undertaking. We had to document every single procedure, from how we log an incoming engine from Cummins to the exact torque specifications we use on our assembly line. It forces everyone in the company to work from the same playbook. This is incredibly important in manufacturing. It means the 100th generator set that rolls off our line is built to the exact same standard as the first one. It also means that if a problem ever occurs, we have a system for traceability. We can track the issue back to its source and fix the process so it never happens again.

That certificate represents a factory's promise to a customer. It says, "We have invested the time and money to build a professional system because we are serious about quality." The annual audits keep us sharp. They ensure we don't just create the system, but that we live by it every single day.

Does a factory get certified just to impress you? Understanding their real motivation gives you better insight into them as a potential partner.

Companies need ISO certification for two main reasons. First, for themselves, to improve efficiency and reduce errors. Second, for their customers, to prove their credibility and gain access to quality-focused global markets.

A company like ours has several reasons to be ISO certified. The most obvious one is that customers demand it. It's often a basic requirement to even be considered for a project. It opens doors to markets in Europe, Oceania, and beyond where quality standards are high. But the internal reasons are just as important. An ISO system makes our factory run better. It helps us reduce waste, catch problems early, and train new employees effectively. A well-run factory is a more profitable factory. This is why a supplier's willingness to invest in certification is such a positive sign. It shows they are thinking long-term.

Now, I have to be honest with you, my dear reader. This is important. I have visited factories that have a beautiful ISO certificate hanging on the office wall, but what I see on the factory floor doesn't match. They passed the audit, but they don't follow the processes every day. The certificate proves they know the standard. A factory visit proves they live the standard. This is why we always encourage our partners to come and see our facility in person. A certificate is a promise. Seeing the tidy workshops, the documented procedures at each station, and the disciplined testing process is the proof.

An ISO certificate is a key sign that a supplier is committed to quality. However, the truest proof comes from visiting the factory to see their certified processes in action.

Rikey Chen