Choosing an alternator is tough because the most important parts are hidden inside. A bad choice can damage equipment and hurt your reputation. I'll show you what really matters.

A good alternator delivers clean, stable electricity because it is built with high-quality internal parts. This includes pure copper windings, superior varnish and insulation, and precisely stamped laminations. These hidden factors ensure long-term reliability and protect the equipment it powers.

To really understand what makes an alternator good, we need to look closer. The differences aren't always visible on the outside. But they become very clear over time, especially when they power expensive machinery. Let's start with the basics to see why these internal details are so important.

You know an alternator makes power, but do you know how? Understanding this simple process helps you spot quality differences later. It’s the foundation for making a smart choice.

An alternator works by using electromagnetic induction. A spinning magnetic field, called the rotor, moves past stationary coils of wire, called the stator. This movement creates an alternating current in the coils, which is the electricity your generator set delivers.

An alternator has two main parts that work together to make electricity. This process is simple but depends on precision and quality materials to work well. Let's break down how it works.

The rotor is the spinning part inside the alternator. Its job is to create a magnetic field. In brushless alternators1, which are common in diesel generators, a small exciter provides power to the rotor windings. This creates the magnetism needed for the next step. The rotor's balance and build quality are very important for smooth operation.

The stator is the fixed outer part of the alternator. It is made of a stack of thin steel plates, called laminations, with coils of copper wire wrapped around them. When the rotor's magnetic field spins past these coils, it induces a voltage and creates an electric current. This is the power that goes to your equipment.

As the engine turns the rotor, the magnetic field sweeps across the stator windings again and again. This constantly changing magnetic field is what generates the alternating current (AC). An Automatic Voltage Regulator (AVR)2 monitors the output voltage. It adjusts the current to the rotor to keep the output power steady and stable.

An alternator that looks great on the outside can hide poor quality within. This can lead to big problems and unhappy clients. Let’s look at what really makes an alternator good.

A good alternator provides clean, stable power with very little voltage fluctuation. It is built with excellent internal parts like pure copper windings and top-grade insulation. This ensures it runs efficiently and reliably for a long time, even under heavy loads.

The true quality of an alternator is found in its internal construction. You can't see these things, but they determine performance and lifespan. For example, have you ever noticed the lights flicker when a generator is running? That's a sign of unstable power from a lower-quality alternator. For lights, it's just annoying. But for sensitive or expensive machinery, unstable power can shorten its life and cause failures. As a power product provider, protecting your client's equipment is key. Here are the hidden factors that truly matter.

| Key Factor | Why It Matters | Signs of Quality |

|---|---|---|

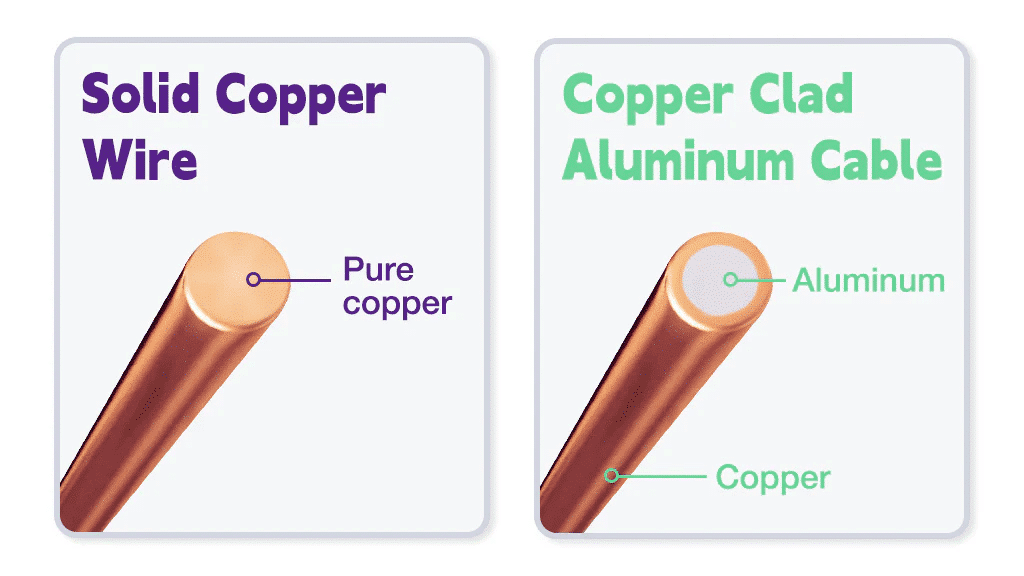

| Enameled Wire3 | Pure copper wire has better conductivity and heat resistance than copper-clad aluminum. This means higher efficiency and less risk of overheating. | Manufacturer specifies 100% copper windings. |

| Varnish & Insulation | Good varnish protects the windings from moisture, vibration, and heat. It prevents short circuits and extends the alternator's life. | Even, thick coating on windings. High insulation class (e.g., Class H). |

| Lamination Stamping4 | Precisely stamped and stacked steel laminations reduce energy loss (eddy currents). This improves overall efficiency and keeps the alternator cooler. | Smooth, tightly stacked core with no burrs. |

| Winding Pitch5 | The design of the windings affects the shape of the electrical wave (waveform). A good design minimizes distortion, protecting modern electronics. | Low Total Harmonic Distortion (THD), typically under 5%. |

These details are what separate a reliable alternator from one that will fail you.

An alternator failure can stop a project completely. Spotting the early warning signs can save you from expensive downtime and repairs. Are you watching for them?

The main signs of a bad alternator are flickering lights, unstable voltage readings, strange grinding or whining noises, and the unit overheating. These symptoms point to internal problems that can lead to total failure if not addressed.

From my experience, alternator problems usually don't happen all at once. They start with small signs. As an equipment provider, you or your service team must know what to look for. Ignoring these red flags can turn a small issue into a catastrophic failure that damages the equipment the generator is supposed to protect. The problems usually fall into two categories.

The most common sign is unstable power output. You might see this as flickering or dimming lights. If you connect a multimeter, you may see the voltage fluctuate wildly, especially when you add or remove a load. For sensitive electronics, this unstable power is very damaging. It can cause control boards to fail or motors to run inefficiently, leading to premature burnout. An alternator that can't maintain a steady voltage under load is a serious liability.

You can also hear or feel when an alternator is going bad. A common sign is a whining or grinding noise, which often points to failing bearings inside. Another major red flag is overheating. If the alternator is too hot to touch after running for a while, it could be due to poor insulation, bad windings, or a failing cooling fan. These physical issues create stress on the entire unit and will eventually lead to a breakdown.

Choosing the right alternator can feel like a choice between price and quality. How do you find the right balance for your project without overspending or risking failure?

Choose an alternator based on how your client will use the generator. For frequent, critical use, you must invest in a premium alternator. For occasional emergency backup, a standard, more affordable model can work well.

The most important advice I can give is to match the alternator to the job. Not every project needs the most expensive option. Your value as a power product expert comes from providing a solution that is both reliable and cost-effective. Here’s how I advise my partners to think about it.

If your customer only needs the generator for occasional power outages, and each use is just for a few hours, you can save them some money on the alternator. It’s a smart way to stay competitive. However, if the customer will use the generator frequently as a prime power source, for example at a mine site or a remote construction project, you must advise them to invest in a top-quality alternator. A failure in that situation would be far more costly than the initial savings.

Here is a simple way to compare the options:

| Consideration | High-Frequency Use (Prime Power) | Low-Frequency Use (Standby Power) |

|---|---|---|

| Investment Priority | Long-term reliability and fuel efficiency. | Lower initial purchase cost. |

| Component Quality | Must have 100% copper, Class H insulation. | Standard quality is often acceptable. |

| Recommended Brands | Invest in proven names like STAMFORD, LEROY SOMER. | A reliable house brand can be a good choice. |

| Long-Term Cost | Higher initial cost, lower lifetime cost. | Lower initial cost, potentially higher repair costs. |

At LONGKAI POWER, we understand this. We offer generator sets with world-class alternators like STAMFORD and LEROY SOMER for the most demanding jobs. We also manufacture our own LONGKAI alternators. Even with intense price competition, we refuse to cut corners on the things you can't see. We use quality materials and the right processes because we know that is what delivers true long-term value.

A good alternator relies on its internal quality to provide stable power. Always match the alternator's quality to the application's demands to get the best performance and long-term value.

Understanding brushless alternators can enhance your knowledge of efficient power generation in diesel generators. ↩

Exploring the role of an AVR can help you grasp how voltage stability is maintained in electrical systems. ↩

Explore this link to understand how Enameled Wire enhances efficiency and reduces overheating in electrical systems. ↩

Explore this link to understand how lamination stamping enhances efficiency and reduces energy loss in electrical systems. ↩

Discover the importance of Winding Pitch in minimizing distortion and protecting modern electronics. ↩

Rikey Chen